Industries We Serve

Husky enables the production of finished products for many consumer and medical markets. Including medical diagnostic devices, food and beverages, thin-wall packaging, closures, consumer goods, electronics, and more.

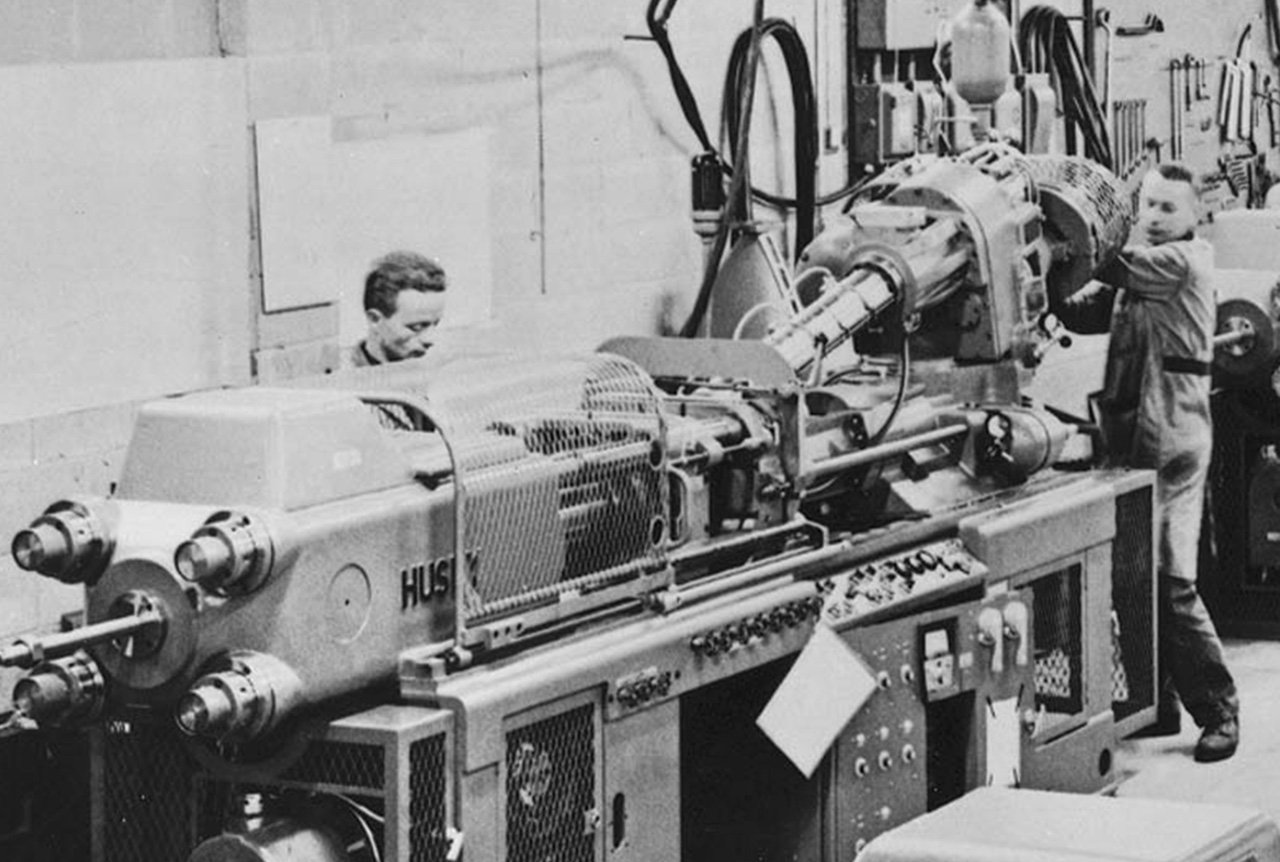

Husky delivers industry-leading injection molding machines and systems engineered for maximum productivity and superior part quality. Since 1953, our engineering excellence has set the standard for performance, efficiency, and reliability in plastic processing.

With integrated systems for molding PET preforms, closures, packaging, and specialized applications, we provide comprehensive manufacturing solutions that enable the lowest total cost to produce across diverse markets.

Husky enables the production of finished products for many consumer and medical markets. Including medical diagnostic devices, food and beverages, thin-wall packaging, closures, consumer goods, electronics, and more.

Husky offers more than just systems and equipment. We gain a full understanding of your business, how it operates, what your objectives are, and the needs of your own customers before we recommend anything. We will work with you to arrive at just the right manufacturing solution. Then we will deliver, install and set up your new Husky onsite to ensure you are up and running according to your exact specifications.

We will also provide training for your employees to ensure that they can fully operate your new Husky system on their own. Additionally, we stay connected with you throughout the life of your system with genuine OEM parts, technical assistance and problem-solving support. And we’re here for you with proactive, predictive and transparent services, such as Advantage+EliteTM, in which we call you before a problem occurs. We utilize the power of remote connectivity through our proactive remote monitoring center to monitor your system. And if we notice a decline in equipment performance, we are already on top of it before you even notice—which helps avoid unplanned downtime.

Simply put, investing in Husky systems, solutions and services is worth it. From the moment you purchase your first system to years down the road—long after lesser systems and products begin to experience problems or fail prematurely. We are with you every step of the way to ensure optimal performance and lowest total cost-of-ownership. Discover the many other differences that make Husky a good business decision when selecting a quality injection molding partner. Including proactive, predictive and transparent services, process and production monitoring, extended protection and maintenance plans, machine audits, equipment refurbishments and upgrades, and more.

Since 1953, Husky has grown to become a global leader in injection molding systems and services to the plastics industry, with over 4,300 employees in 35 locations worldwide, supporting our customers in over 140 countries. Learn more about our customer-first philosophy.

Husky is here for its customers, prospective customers, partners and communities—whatever you need, whenever you need it. Simply complete our form and we’ll do the rest. You can count on it.

Give us a call at 1 (905) 951 5000.