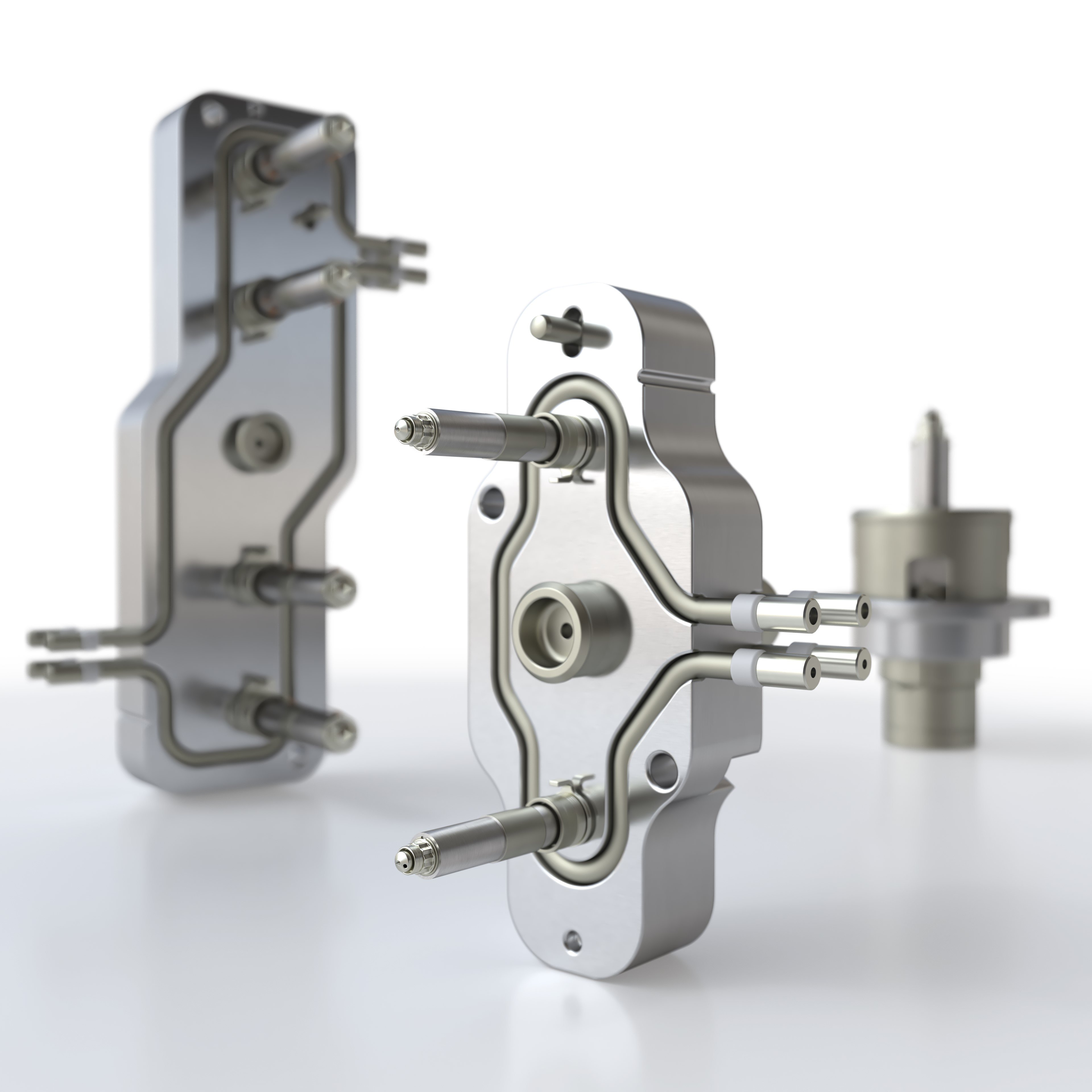

When you want the best in melt management and material flow characteristics, while reducing shear and stress, Husky custom hot runners are the way to go. They are a complete tooling solution, helping you achieve the highest levels of part quality and part volume at the lowest part cost. And they are available in both hot tip and valve gate configurations, optimized for your specific application. Choose from two-, three- and four-level systems, plus a multitude of sprue bar configurations, including split-sprue, which can handle throughputs up to 1,500 g/s. As the industry’s leading hot runner system supplier, Husky products and people give you the edge.

Husky hot runners for injection molding deliver melt-to-the-mold with:

- High gate quality

- Excellent cavity-to-cavity balance

- The fastest color changes

- Total design freedom

- Highly customizability

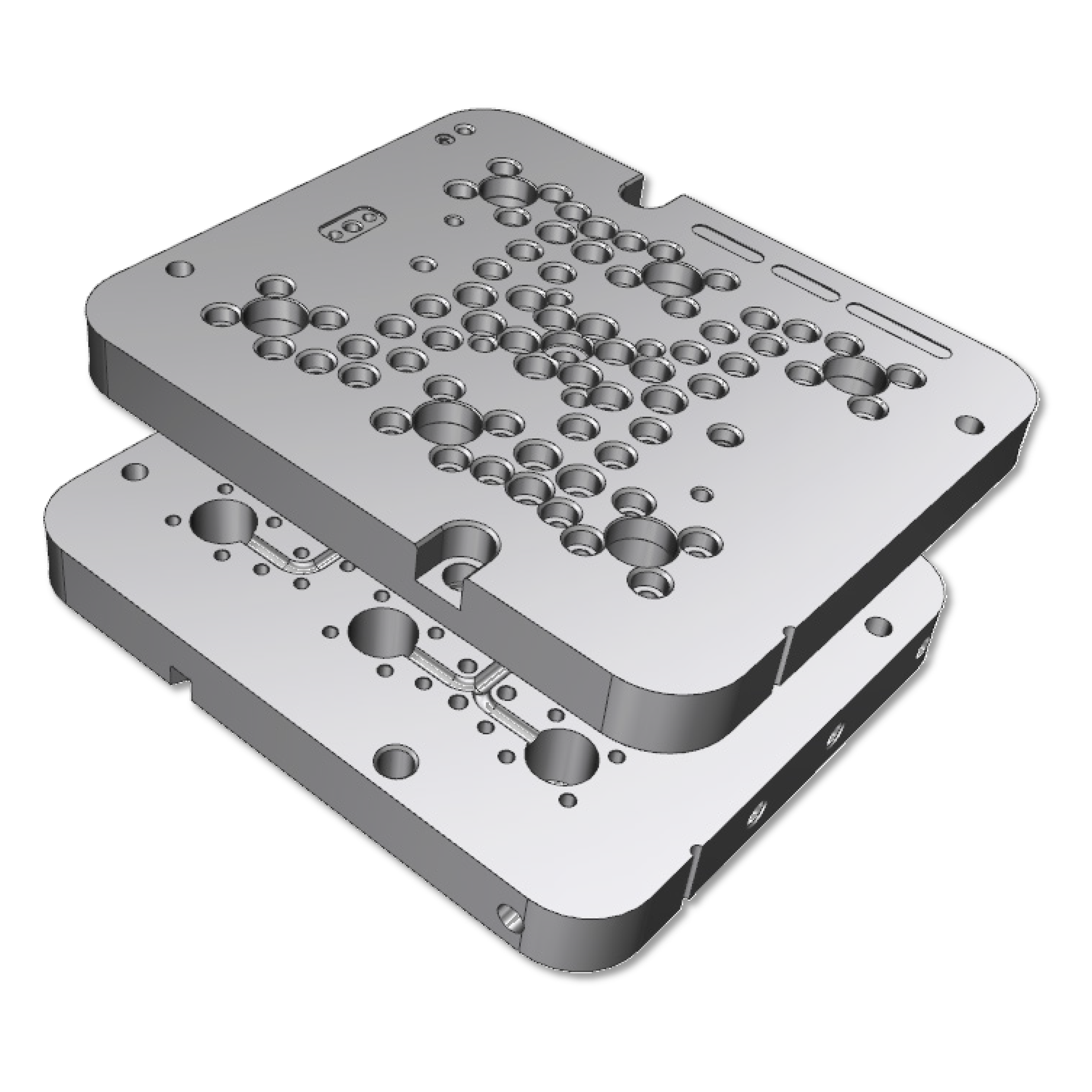

Single-face, high-cavitation systems.

Our high-cavitation hot runners for 24 to 128 drops and higher offer optimum cycle times, easy color changes and perfectly balanced operation. They are available with a complete range of nozzle sizes and gating styles for all applications. They ship to you ready-to-go, fully assembled and tested.

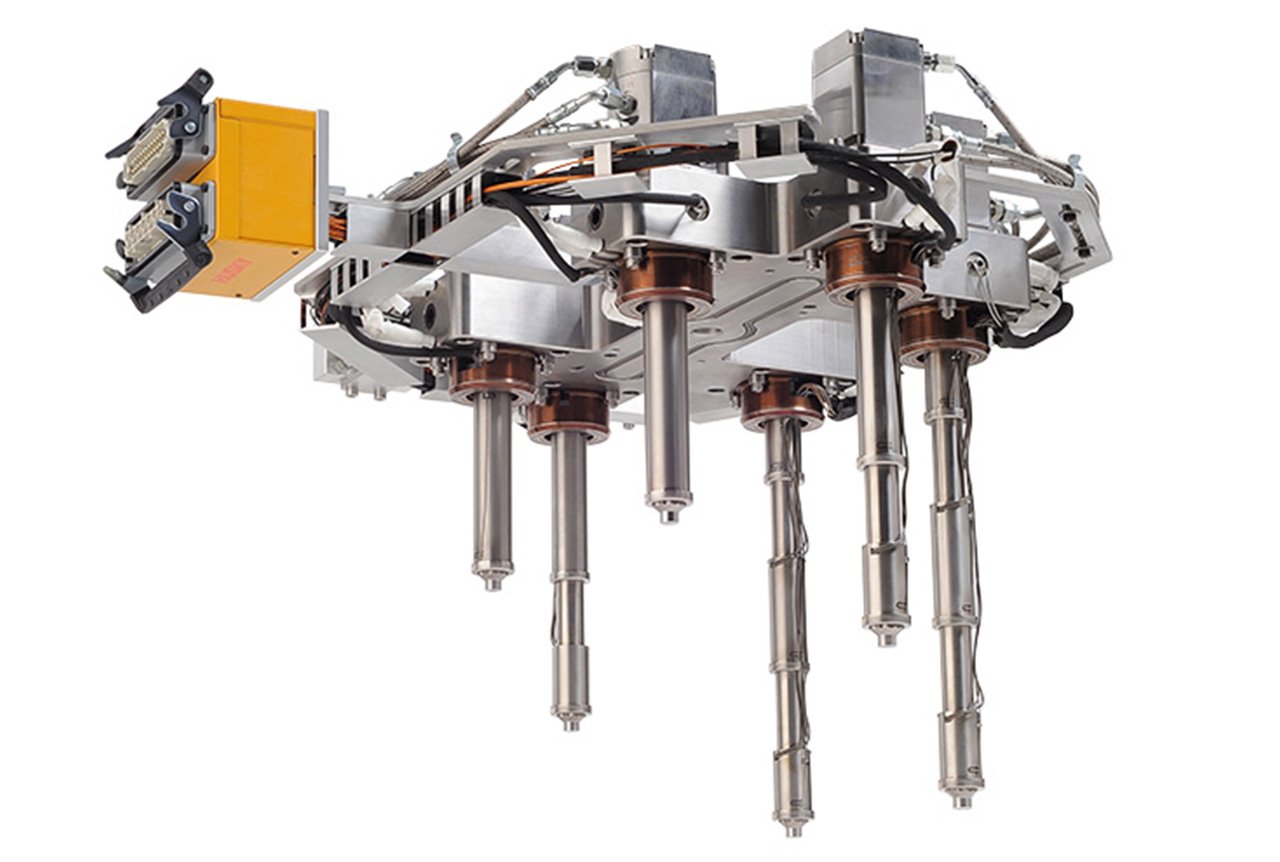

Stack hot runner systems.

No matter how you stack it—two-, three- or four-level—Husky hot runners are performance-proven and low-maintenance. Operator-friendly, too. And they’re available with a multitude of sprue bar configurations.

Nonsymmetrical systems.

Do you need nonsymmetrical and family mold system solutions? We offer a complete range of systems that can be optimized and balanced with our flow simulation program.

Multi-material systems.

From 2+2 to 64+64 valve gates, no one has more experience with multi-material and multicolor systems than Husky. We offer the expertise to design solutions to your most challenging applications.

Split-sprue bar technology.

Keep your molding area clear from free-dropping parts. Our sprue bar technology features stem-to-stem shutoff to prevent traditional hot runner drool and stringing.

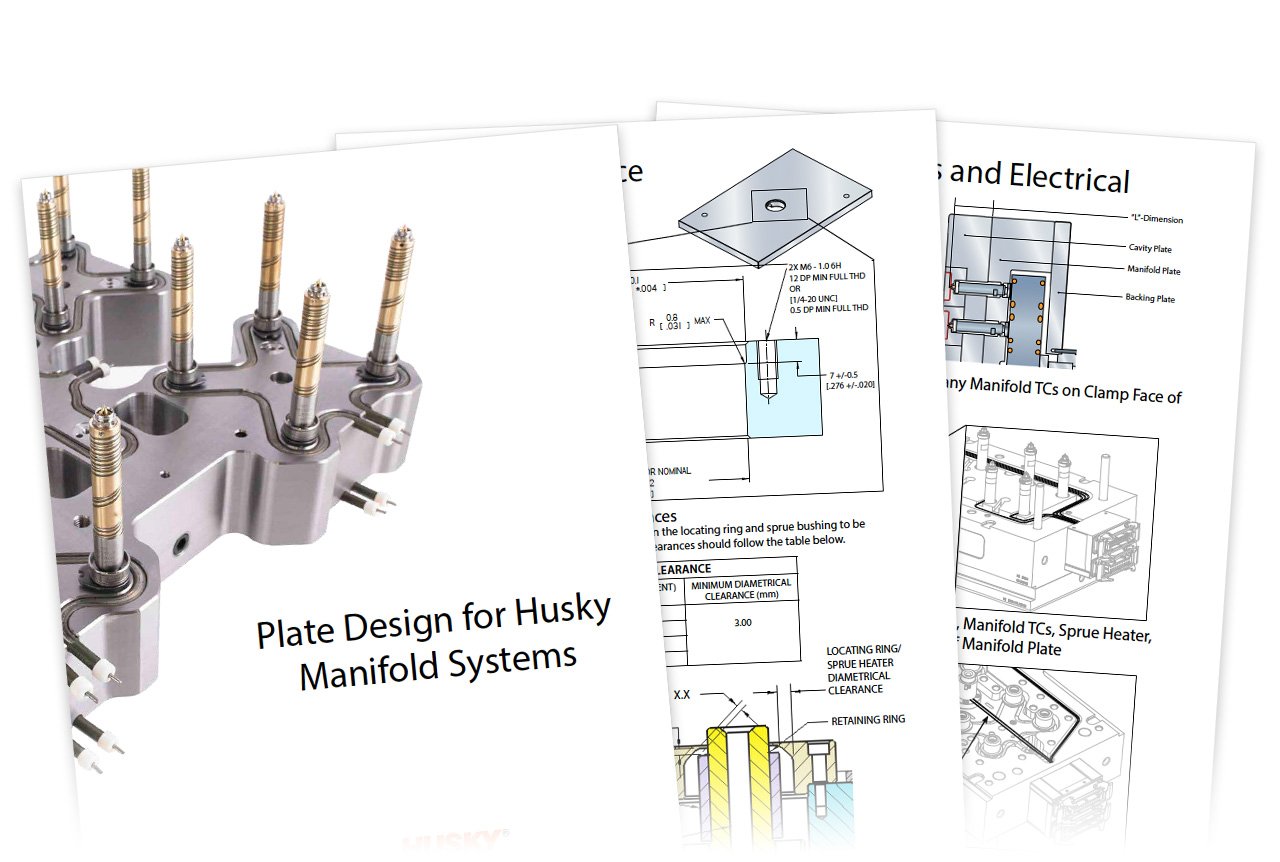

Superior support.

Husky hot runners are backed by a 3-year leak-proof guarantee, strong maintenance programs to keep them running reliably at top capacity, plus a refurbishment program that can save you as much as 40% compared to the cost of a new hot runner system.

Our hot runner services include:

- Application review to identify the best hot runner technology

- Flow simulation and resin testing

- Finite element analysis

- Hot runner refurbishment

- 24/7 spare parts availability and local service support