PET Packaging: Driving Sustainability & the Circular Economy

As sustainability and circular compliance pressures mount, manufacturers and brands relying on single-use, short-lifecycle, or multi-material packaging are actively rethinking their strategies. Many are now transitioning to PET to stay competitive and avoid non-compliance with global legislative efforts that are aiming to increase recycling and promote the use of recycled content.

The most prominent might be the European Union's Single Use Plastic (SUP) legislation that sets the minimum recycled content requirements for member states. The SUP Directive in Europe focuses on phasing out single-use plastic items and increasing usage of recycled content in plastic bottles. The draft version of the Packaging and Packaging Waste Regulation that is pending approval includes expanding recycled content requirements to plastic packaging beyond bottles and setting 2040 requirements for plastic packaging.

Several countries within South America, including Colombia, Chile, and Uruguay have established recycled content mandates for PET bottles. Meanwhile in North America, U.S. states like New Jersey, Washington, and California have set targets for 15% to 25% recycled content by 2025.

In this article, we’ll take a closer look at the advantages of PET and why it has become the go-to material for food and beverage packaging in today’s circular economy.

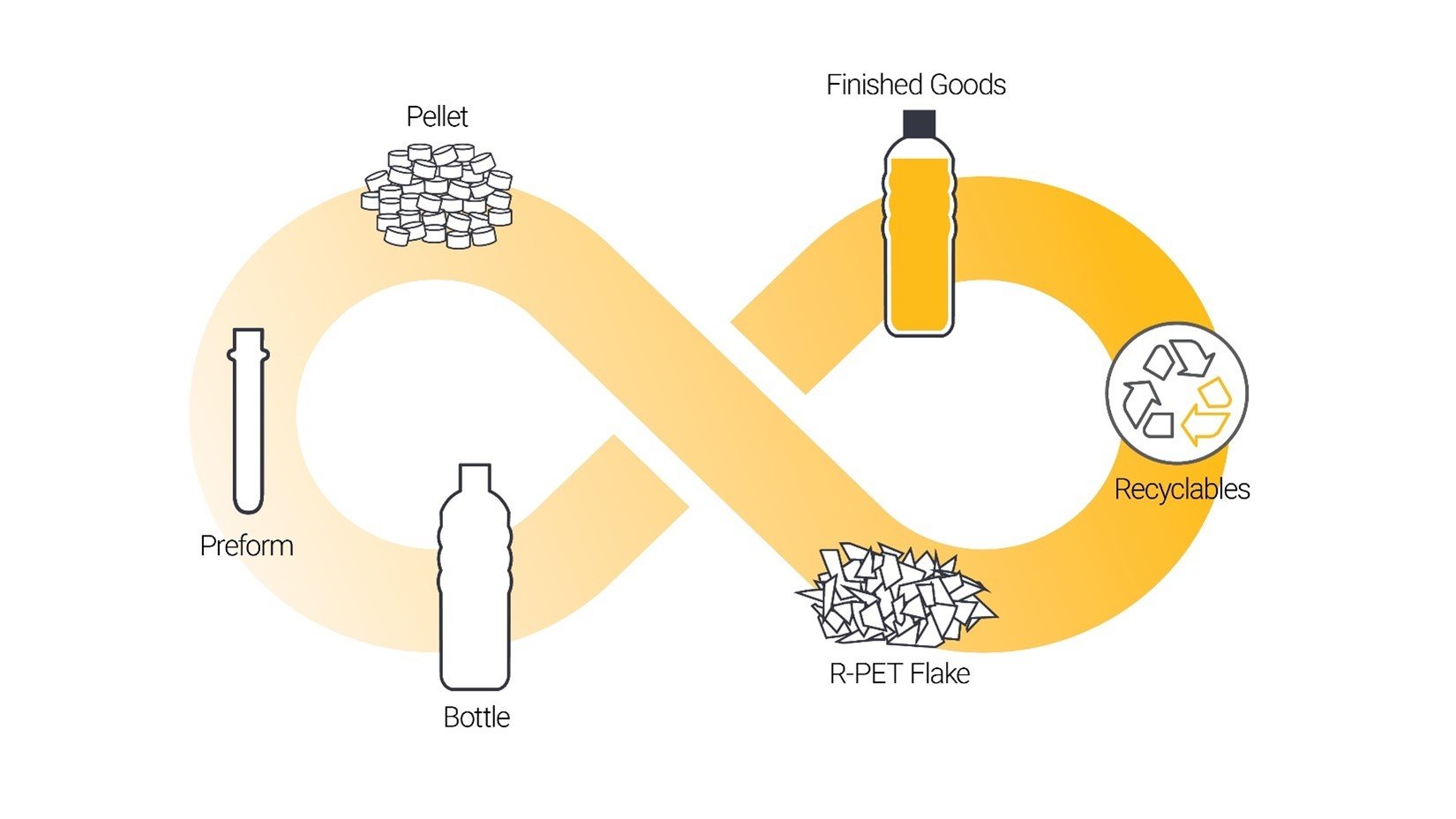

What Is the Circular Economy?

The circular economy is a term that has been used to describe a regenerative system designed to minimize waste while maximizing resource efficiency. Its core principles include designing products for durability and recyclability, reusing materials, and recovering resources at the end of their lifecycle through recycling.

In the food and beverage packaging industry, circular economy initiatives have focused on legislative requirements and industry standards that promote sustainable packaging and recyclability, setting a clear framework for compliance and best practices.

Why PET Is the Material of Choice for Circular Packaging

Compared to aluminum, glass, and carton, there are a number of advantages PET provides to manufacturers and brands looking to meet new sustainability standards. These include:

1) Immediate Environmental Benefits

PET produces lower greenhouse gas emissions, consumes less energy, and generates less waste compared to commonly used alternatives. Its fully recyclable components also support a closed-loop system that minimizes resource depletion and reduces environmental impact.

A recent study by The National Association for PET Container Resources (NAPCOR) comparing beverage container systems for carbonated soft drinks and still water found that PET:

- Consumes less energy during production

- Generates less solid waste

- Uses less water

The study estimated that over the course of a year, PET bottles could save approximately 4.4 billion litres of water, equivalent to removing approximately 688,000 gas-powered cars from the road, and diverting approximately 138 million bags of trash from landfills in the United States.

Real-world Conversion

A European-based pasta sauce brand recently made a significant shift in their packaging strategy by moving from traditional glass and aluminum cans to PET jars. To facilitate this change, the brand implemented specialized hot-fill technology that enables the pasteurization of products and supports a hot filling process at temperatures of up to 95ºC. The new PET jars leverage a crystallized neck to enhance stability, and also eliminate BPA liners, addressing consumer concerns about chemical exposure. The jars are approximately eight times lighter than their glass replacements, resulting in reduced transportation costs and a lower environmental impact. |

2) Increased Design Flexibility for Circular Packaging

Thanks to PET’s inherent versatility, manufacturers can leverage design flexibility to support a range of circular packaging initiatives, including:

- Lightweighting: PET enables the creation of lightweight packaging that reduces plastic use, CO2 emissions, and resin consumption.

- Label-free packaging: PET supports label-free designs, simplifying recycling, reducing contamination, and minimizing non-recyclable waste.

- Mono-material packaging: Having bottle and closure that are both made from PET makes it easier to improve the sustainability and circularity of the entire beverage package, simplifying the recycling stream and having the required infrastructure is already in place.

- Premiumization: PET allows brands to elevate their packaging through strategies like thermochromic color effects, luminescent designs, unique bottle shapes, and collapsible packaging.

Real-world Conversion

|

The conversion of a ready-to-serve soup company provides a strong example. In 2020, the company transitioned its line of soups from a 1 litre multi-material carton to a 750 ml PET bottle. This 100% recyclable, bottle-to-bottle solution enabled a new premium look for the brand and added UV protection, all while enhancing the consumer experience in a number of ways, including better pouring with no splash. Additionally, the switch to PET enhanced pallet stability and overall bottle performance, contributing to a 20% price point increase. |

3) Cost Efficiency and Production Optimization

PET provides a reliable supply chain even in the face of rising energy costs and disruptions. Its design flexibility supports customizable packaging solutions that meet market and sustainability demands.

Real-world Conversion

|

A prime example of PET's production benefits can be seen in the pharmaceutical sector, where medicinal syrups have traditionally been packaged in glass. In a recent case, a Husky customer leveraged our team’s expertise in PET technology, including prototyping and trials, to successfully transition from a glass to PET bottle. The move resulted in a 27% reduction in part costs and transitioned production from a one-stage to a two-stage process, increasing production flexibility. Importantly, the use of medical-grade PET ensures compliance with the pharmaceutical industry’s high industry safety and quality standards. |

The Increasing Importance of rPET

Recycled PET (rPET) is primarily sourced from used PET bottles collected through formal recycling systems and involves sorting, washing, decontaminating, repairing the material, and transforming PET bottles into flakes and pellets. Quality control measures then check critical properties, such as intrinsic viscosity and acetaldehyde levels to ensure product specifications are being met.

While rPET is commonly blended with virgin PET, there is a growing trend toward using 100% recycled content. Husky provides detailed rPET specification sheets for food-grade pellets and flakes, including recommended sizes, contamination limits, viscosity ranges, crystallinity, and melting points.

Maximize PET Packaging Potential with Husky COMPLETE™

Husky COMPLETETM gives PET preform and packaging producers the ability to transform variability into stability throughout production, enabling world-class productivity and the highest quality, most sustainable packaging – at the lowest cost.

Husky COMPLETETM with Advantage+EliteTM provides real-time monitoring that proactively secures and maintains the lowest total cost of production, including:

- Increasing availability, performance, and quality

- Eliminating the cost of emergencies

- Reducing material and energy usage and

- Increasing plant knowledge and capability

Husky COMPLETE™ is supported by our latest generation platform of HyPET®, Hylectric®, and HyperSync® systems, and we work closely with OEM partners to refine and evolve our injection molding technology, maintaining the highest requirements for package performance and consumer experience.

Next Steps

Reach out to our team of PET experts to learn more about how we can enable your switch to a circularly compliant package. Book a Circular Packaging Assessment and Husky’s packaging experts will assess your production and packaging needs, recommend the best strategy for circularity, and much more.