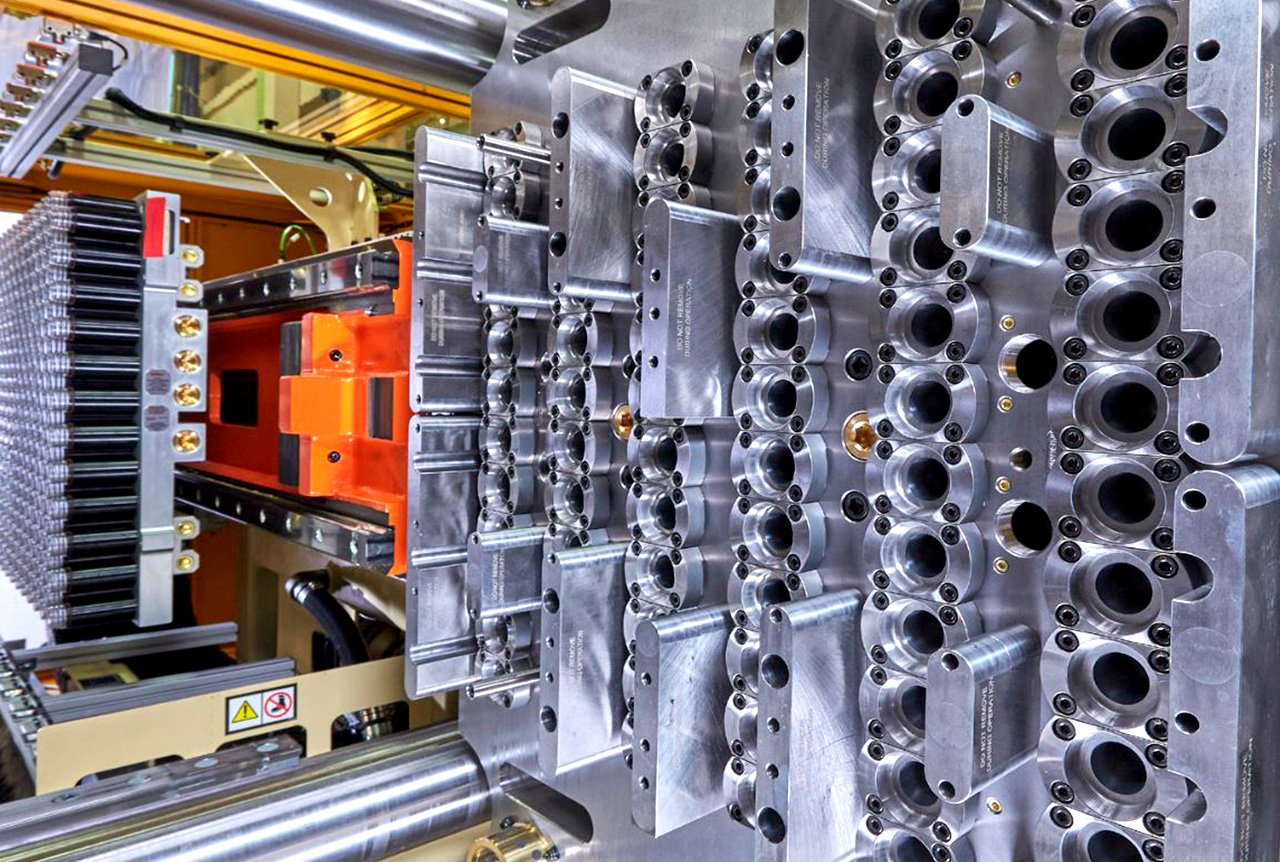

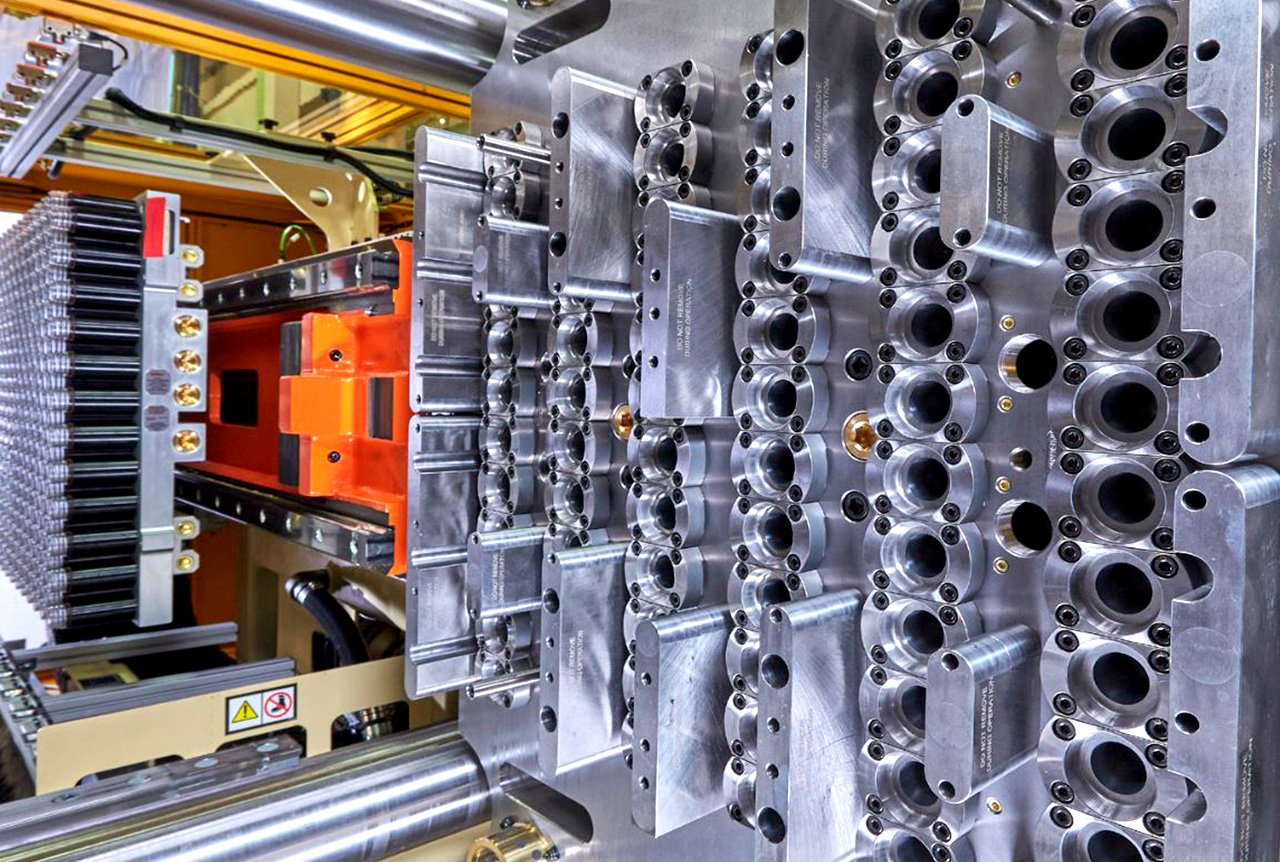

Mold Solutions

Trust the world’s largest mold maker to help you choose the right mold for food, beverage and consumer goods applications. See how Husky’s PET molds can increase your profitability.

PET and rPET manufactured products are where tomorrow’s food, beverage and consumer goods markets are headed. With Husky PET Tooling technologies and PET molds at the heart of your Husky PET system, you have a competitive edge, leveraging solutions that intimately connect machine and mold to deliver revolutionary capabilities resulting in ever-lighter, stronger PET preforms and more profitable production.

These solutions include advanced PET mold conversions to implement new, weight-saving product configurations and new, faster mold changes that reduce cold half change times by up to 60%. Optional self-cleaning technology on our select molds and cold halves can help you save hundreds of hours of maintenance annually. Plus, our advanced NexPETTM mold is a flexible tool for shorter production runs and frequent changeovers. Finally, to restore preform quality with the least possible downtime, go with Husky Express Refurbishments or Conversions, which drastically reduce the amount of time it takes for traditional mold refurbishments and conversions from weeks down to a matter of hours. Husky ships you the necessary plates and required stack parts directly, so you can implement the fastest possible changeover, right on site.

Trust the world’s largest mold maker to help you choose the right mold for food, beverage and consumer goods applications. See how Husky’s PET molds can increase your profitability.

Husky is here for its customers, prospective customers, partners and communities—whatever you need, whenever you need it. Simply complete our form and we’ll do the rest. You can count on it.

Give us a call at 1 (905) 951 5000.